Introduction

Slurry pumps work hard every dahttp://goody.

1. Pick the Perfect Pump for the Job

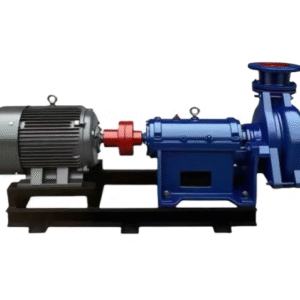

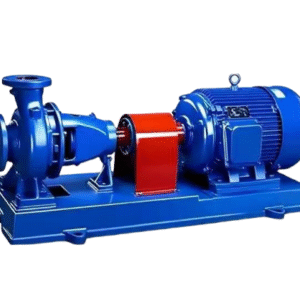

Not all slurry pumps work the same way. Some handle large rocks better while others move fine particles more efficiently. Always match the pump type to your specific slurry mixture.

For example, centrifugal pumps work well for watery slurries. Meanwhile, positive displacement pumps handle thicker mixtures better. Choosing wrong causes extra wear and wastes energy.

2. Keep an Eye on Wear Parts

Slurry pumps have parts that wear out quickly. The impeller, liner, and seals take the most damage. Check these parts often and replace them before they fail completely.

Signs of wear include reduced flow rate and strange noises. Catching problems early saves money and prevents breakdowns. Make wear part inspection part of your weekly routine.

3. Control the Flow Speed

Running your slurry pump too fast causes damage. But running it too slow leads to settling and clogging. Find the sweet spot for your specific material.

Most manufacturers provide ideal speed ranges. Stick to these guidelines. If unsure, start slow and gradually increase until you get good flow without vibration.

4. Use the Right Lubrication

Slurry pump bearings work under tough conditions. They need special grease that won’t wash out or break down. Always use lubricants made for heavy-duty slurry pumps.

Apply grease regularly but don’t overdo it. Too much grease attracts dirt. Follow the manufacturer’s schedule for best results.

5. Clean Properly After Use

Never let slurry dry inside your pump. It hardens like concrete and damages components. Always flush the system with clean water after each use.

For stubborn buildup, use mild cleaning solutions. Avoid harsh chemicals that might corrode metal parts. A clean pump lasts much longer between repairs.

Bonus Tip: Monitor Performance Daily

Keep simple records of flow rates and power use. Changes in these numbers often signal developing problems. Tracking performance helps you fix issues before they become serious.

Why These Methods Work

These five easy ways to supercharge your slurry pump focus on prevention. They stop small problems from becoming big ones. Best of all, they don’t require special skills or expensive tools.

Common Mistakes to Avoid

Many operators ignore early warning signs. Others use the wrong replacement parts to save money. These shortcuts always cost more in the long run. Stick to quality parts and regular maintenance.

When to Call a Professional

Some problems need expert help. If you see major leaks, severe vibration, or sudden performance drops, call a technician. Trying to fix these yourself might cause more damage.

Long-Term Benefits

Following these five easy ways to supercharge your slurry pump brings many advantages. You’ll see lower energy bills, fewer breakdowns, and longer equipment life. The small time investment pays off quickly.

Final Thoughts

Slurry pumps don’t have to be troublesome. With basic care and attention, they can work smoothly for years. Start using these five easy methods today and see the difference.