If you’ve ever wondered what a slurry pump is, you’re in the right place. First off, let’s keep it super simple—slurry pumps are just special pumps made to move “slurry.” Now, what’s slurry? It’s a mix of liquid (like water) and solid bits (like sand, dirt, or even small rocks). Regular pumps can’t handle that mix because the solids would break them or get stuck. But slurry pumps? They’re built for this tough job, so they don’t get ruined easily when moving that thick, chunky mix.

Next, let’s talk about where you actually see slurry pumps in action. You might not notice them every day, but they’re everywhere in jobs that deal with messy, solid-liquid mixes. For example, in mines, workers use slurry pumps to move the mix of water and mined rocks out of the mine. On construction sites, they use slurry pumps to clear out mud or gravel from holes they dig. Even in wastewater treatment plants, slurry pumps help move the thick, solid-filled water so it can get cleaned. Basically, any place where you need to move something that’s not just plain liquid—slurry pumps are the go-to tool.

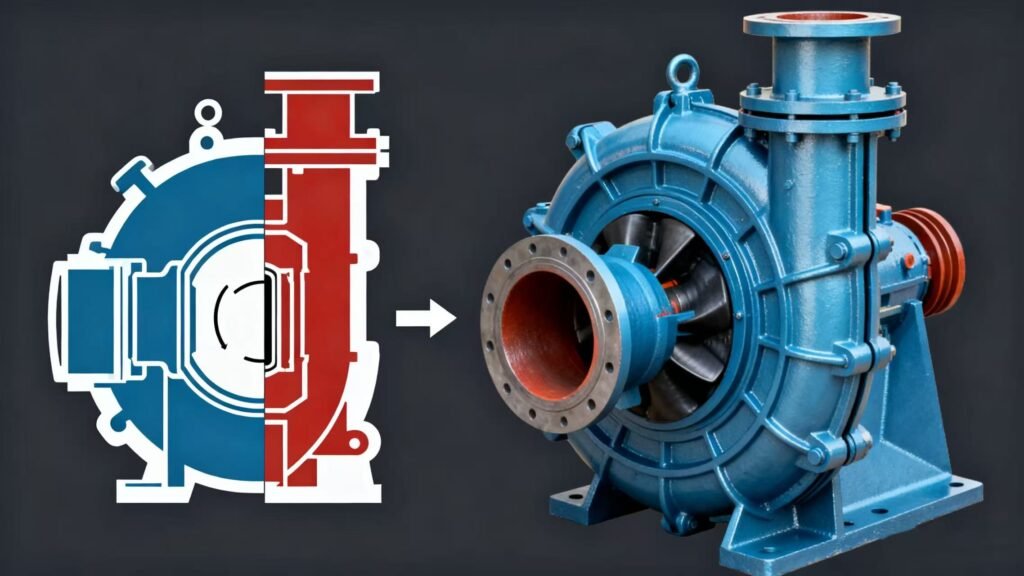

Now, let’s break down what makes a slurry pump different from a regular pump. Regular pumps have smooth parts inside, right? Those parts can scratch or break if solids hit them. But slurry pumps have tough, thick parts made from strong materials like rubber or hard metal. These materials can handle the solids rubbing against them without getting damaged. Also, slurry pumps have bigger openings where the slurry goes in and out. Regular pumps have small openings that would clog up with solids, but the bigger openings on slurry pumps let the chunky mix flow through easily. That’s why slurry pumps don’t get stuck as much—they’re designed for that messy mix.

Another key thing to know is that slurry pumps come in different types, and each type works best for different jobs. The first common type is the “centrifugal slurry pump.” This one uses a spinning part (called an impeller) to push the slurry out. It’s great for moving slurry that’s not too thick—like the mix of water and fine sand you might find on a beach cleanup. Then there’s the “positive displacement slurry pump.” This type uses gears or pistons to squeeze the slurry through, which makes it perfect for super thick slurry—like the heavy mud you’d find in a construction ditch. Choosing the right type of slurry pump matters because if you use the wrong one, it might not work well or could break fast.

Let’s move on to why slurry pumps are so important—especially for big industries. Think about mines again: if a mine didn’t have slurry pumps, workers would have to carry that heavy rock-and-water mix by hand. That would take forever and be super tiring. With slurry pumps, they can move tons of slurry quickly, which keeps the mine working smoothly. The same goes for construction: without slurry pumps, digging a big hole would take way longer because workers couldn’t clear the mud fast. Slurry pumps save time and energy, and they help industries keep up with their work. Without them, a lot of the things we use every day—like metals from mines or new buildings—would take much longer to make.

Now, let’s talk about how to take care of a slurry pump so it lasts a long time. Even though slurry pumps are tough, they still need regular checks to stay in good shape. First, you should always check the “seals” on the slurry pump. Seals are the parts that keep the slurry from leaking out. If a seal is broken, slurry can leak and damage other parts of the pump. Second, you need to clean the slurry pump after using it. If you leave dried slurry inside, it can clog the pump the next time you use it. Just rinse it with water to get rid of any leftover solids. Third, check the impeller (that spinning part we talked about earlier). If the impeller is worn down from rubbing against solids, it won’t push the slurry as well. Replacing a worn impeller helps the slurry pump work like new.

Let’s clear up a common mistake people make with slurry pumps: using them for plain water. Some people think, “If a slurry pump can handle thick slurry, it can handle anything!” But that’s not true. Slurry pumps are made for heavy, solid-filled mixes, so using them for plain water is a waste. Plain water doesn’t need that tough, thick design—regular pumps work better and use less energy. Also, using a slurry pump for plain water can make the pump wear out faster because it’s working harder than it needs to. So save your slurry pump for the messy jobs it’s made for!

Another thing to know is how to pick the right size of slurry pump for your job. Size matters a lot here—too small, and the pump can’t move enough slurry. Too big, and it uses too much power. First, think about how much slurry you need to move each hour. If you’re moving a small amount (like from a small garden ditch), a small slurry pump works. If you’re moving tons of slurry from a mine, you need a big one. Then, think about how far you need to move the slurry. If you’re moving it just a few feet, a smaller pump is fine. If you’re moving it across a construction site (like 100 feet or more), you need a bigger pump with more power. Asking a professional for help is a good idea—they can look at your job and tell you exactly what size slurry pump you need.

Let’s talk about the parts of a slurry pump that you might hear about. The first part is the “casing”—that’s the outer shell that holds all the inner parts. The casing is thick and strong to protect the inside from solids. Then there’s the impeller, which we already mentioned—it’s the part that spins to push the slurry. The “inlet” is where the slurry goes into the pump, and the “outlet” is where it comes out. Both the inlet and outlet are big to prevent clogging. There’s also the “motor”—that’s what makes the impeller spin. The motor on a slurry pump is usually more powerful than a regular pump’s motor because it has to move that heavy slurry. Knowing these parts helps you understand how the slurry pump works and makes it easier to fix small problems.

Now, let’s think about safety when using a slurry pump. Even though they’re useful, slurry pumps can be dangerous if you don’t use them right. First, always wear gloves and safety glasses when handling the pump. Slurry can have sharp solids that can cut your hands or get in your eyes. Second, never stick your hand inside the pump while it’s running— the impeller is spinning fast, and it can hurt you. Turn the pump off first if you need to check inside. Third, make sure the pump is on a flat surface. If it tips over while running, slurry can spill, and the pump can get damaged. Following these safety rules keeps you safe and keeps the slurry pump working well.

Let’s talk about how slurry pumps have changed over time. A long time ago, people didn’t have slurry pumps—they used buckets to move thick mixes, which was slow and hard. But as industries grew (like mining and construction), they needed a better way. So engineers started making pumps with tougher parts that could handle solids. At first, these pumps were big and heavy, but now they’re smaller and more efficient. Some modern slurry pumps even have sensors that tell you if something’s wrong—like if the pump is clogging or a part is worn out. This makes it easier to take care of the slurry pump and fix problems before they get worse.

Finally, let’s wrap up with why learning about slurry pumps is useful. Even if you don’t use one every day, knowing what they do and how they work can help you in different ways. If you ever work on a home project (like digging a pond and needing to clear mud), you’ll know that a slurry pump is the tool to use. slurry pumps are just tough tools that make messy jobs easier—and that’s something worth knowing!