If you often deal with liquids mixed with solids—think wet sand, muddy water, or even small stones—you’ve probably heard of slurry pumps. Slurry pumps are tools made just to move this thick, solid-filled mix (we call it “slurry”) from one spot to another. Regular water pumps can’t handle all those solids—they’d get blocked fast—but slurry pumps don’t have that problem. That’s why so many jobs and industries count on slurry pumps every single day.

What Even Is a Slurry Pump, Anyway?

Let’s break it down simply: a slurry pump isn’t like the regular pumps you might use for clean water. If you pour sand or gravel into a regular pump, it’ll clog up right away. But slurry pumps are built tough to handle that mess. They have strong parts that can push thick slurry through pipes without getting stuck. Think of it like a bike vs. a truck—you can’t carry a pile of bricks on a bike, but a truck is made for heavy loads. Slurry pumps do the same for thick, solid-filled liquids.

Why Bother With Slurry Pumps?

Slurry pumps fix a huge problem: moving slurry by hand or with regular tools is a nightmare. Imagine carrying buckets of wet mud across a construction site—your arms would get tired, you’d make a mess, and it would take forever. Slurry pumps make that work easy. They move lots of slurry quickly, so workers don’t have to lift heavy stuff or waste time. Plus, they keep the whole process clean and safe. Without slurry pumps, many jobs would take twice as long (or more!) and be way more dangerous.

Where Do Slurry Pumps Actually Get Used?

Slurry pumps are everywhere—you just might not notice them. Mines use big slurry pumps to move dirt and minerals from underground up to the surface. Construction sites use them to clear mud out of holes they’re digging. Farms even use smaller slurry pumps to move animal waste (which becomes fertilizer later). Wastewater treatment plants also rely on slurry pumps to process dirty water that has solids in it. Basically, any place that deals with thick, solid-filled liquids needs slurry pumps to get the job done.

What Are the Key Parts of a Slurry Pump?

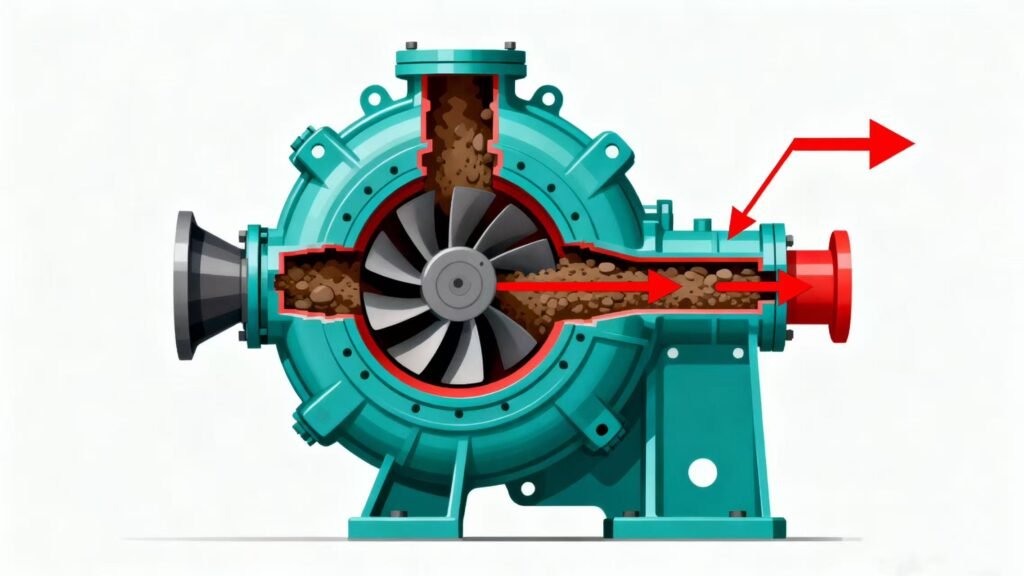

You don’t need to be an expert, but knowing the main parts of a slurry pump helps you understand how it works. First, there’s the “impeller”—it’s a spinning part that pushes slurry forward, kind of like a propeller in a boat. Then there’s the “casing”—a strong shell that holds the slurry and makes sure it moves in the right direction. There’s also the “inlet” (that’s where slurry goes into the pump) and the “outlet” (that’s where it comes out). All these parts work together to keep the slurry pump running

smoothly, no matter how thick the slurry is.

How Does a Slurry Pump Really Work?

It’s way simpler than you might think! First, you connect the slurry pump to a pipe that leads to the slurry you need to move. When you turn the pump on, the impeller starts spinning fast. That spinning creates a force that pulls slurry into the inlet. Then, the impeller pushes that slurry through the casing and out the outlet pipe. The whole thing keeps going nonstop—so as long as the pump is on, it keeps moving slurry without slowing down. That’s why slurry pumps are perfect for jobs that need steady, long-term work.

Are There Different Kinds of Slurry Pumps?

Yes, there are a few main types of slurry pumps, and each one is for a different job. The most common type is the “centrifugal slurry pump”—it uses that spinning impeller we talked about, and it works for most everyday jobs. Then there’s the “positive displacement slurry pump”—it uses gears or pistons to push slurry, and it’s better for extra-thick slurry that’s hard to move. Some slurry pumps are small enough for tight spaces, while others are huge for big mining or construction projects. Choosing the right one just depends on what kind of slurry you’re moving and how much of it there is.

How Do You Pick the Right Slurry Pump?

Picking the right slurry pump isn’t guesswork—you just need to ask a few simple questions. First, what’s in your slurry? Is it sand, rocks, or something else? The solids in the slurry will tell you how strong the pump needs to be. Next, how much slurry do you need to move? A small farm might only need a pump that moves 10 gallons per minute, but a mine might need one that moves 1,000 gallons per minute. Finally, how far do you need to move the slurry? Longer distances mean the pump needs more power to push the slurry that far. Answering these questions helps you find the perfect slurry pump for your needs.

How Do You Take Care of a Slurry Pump?

Taking care of a slurry pump is super important—if you do it right, the pump will last for years. First, you should check the pump regularly for leaks or loose parts. Slurry is rough, so parts can wear out over time. You should also clean the pump after each use, especially if the slurry is sticky (like wet clay). Adding oil to moving parts (like the impeller) helps keep them running smoothly too. If you hear strange noises from the pump or notice it’s moving less slurry, fix it right away—small problems with slurry pumps turn into big, expensive ones fast.

What Are Common Problems With Slurry Pumps?

Even the best slurry pumps have issues sometimes, but most are easy to fix. The most common problem is clogging—if the slurry has big solids, they might get stuck in the inlet or the impeller. You can fix that by turning the pump off and pulling out the stuck solids (just wear gloves to stay safe!). Another problem is worn parts—since slurry is rough, the impeller or casing can get scratched or dented. You can replace those parts to make the slurry pump work like new again. Leaks around the pipes are also common—just tightening the pipes usually fixes that.

How Long Can a Slurry Pump Last?

Slurry pumps can last a long time, but it depends on how you use them and how well you take care of them. A well-maintained slurry pump used for light jobs (like a small farm’s fertilizer work) can last 5 to 10 years. A slurry pump used for heavy jobs (like mining) might only last 3 to 5 years, since it’s working so hard. The type of slurry matters too—slurry with sharp rocks will wear out the pump faster than slurry with soft mud. If you take good care of your slurry pump, you’ll save money because you won’t need to buy a new one as often.

Do You Need Special Training to Use a Slurry Pump?

You don’t need a college degree to use a slurry pump, but you should learn the basics first. Most companies will show you how to turn the pump on and off, how to check for problems, and how to clean it. You also need to know how to stay safe—always wear gloves and safety glasses when working with slurry, since it can be messy or have sharp solids. If you’re not sure how to do something, just ask a professional. Using a slurry pump safely is just as important as using it the right way.

Final Thoughts on Slurry Pumps

Slurry pumps might not be the most exciting tool out there, but they’re essential for so many jobs. They move thick, solid-filled liquids that regular pumps can’t handle, and they make work faster, easier, and safer. Whether you’re in mining, construction, farming, or wastewater treatment, slurry pumps help you get things done without the hassle. Just remember to pick the right slurry pump for your needs, take care of it regularly, and use it safely—then it will work for you for years. Now you know all the key stuff about slurry pumps, so you can talk about them with confidence!