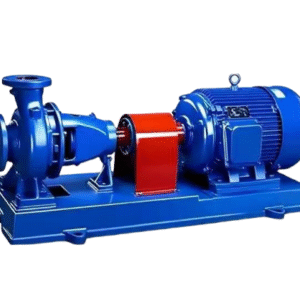

Features

This pump has a simple structure and is easy to maintain. Its unique structural design enables maintenance and replacement of vulnerable parts such as the impeller seal and bearings without disassembling the pipeline. The feed pump of the filter press adopts a unique hydraulic design and impeller installation method, ensuring that its performance curve is steeper than that of general impurity pumps. It is highly suitable for achieving the purpose of large flow, low pressure feeding and small flow, high pressure filtration in response to the changes in resistance during the feed process of the filter press. Its unique hydraulic performance precisely matches the progressive process of the filter press from cavity to filling and then to drying. During the initial feeding stage, do not use valves to control the excessive flow rate, which may cause motor overload. After sealing, the pressure will not cause impact or wear on the filter plate frame, reducing the damage to the filter cloth on the filter plate frame and avoiding vibration caused by impact on the filter plate. The small flow and large pressure in the later stage of filtration are less likely to cause pump blockage. Especially during the later filtration period, the pump operates under high pressure. Its unique impeller installation method and the function of the auxiliary impeller ensure that there is basically no leakage at the shaft seal