If you work with slurry pumps, you know how crucial they are to keeping your operations on track. A well-maintained slurry pump doesn’t just last longer—it also works more efficiently, saving you time and money in the long run. The good news is that taking care of your slurry pump doesn’t have to be complicated. With a few simple habits and regular checks, you can keep your slurry pump running smoothly for years to come. Let’s dive into the easy, practical steps that any operator can follow to boost their slurry pump’s performance and lifespan.

Start with Daily Visual Inspections for Your Slurry Pump

First things first, make a daily visual check part of your routine—your slurry pump will thank you for it. Walk around the slurry pump and look for any obvious issues like leaks, loose bolts, or unusual wear on hoses and connections. Pay close attention to the pump’s casing and impeller area; even small cracks or buildup can lead to big problems down the line. If you spot something off, don’t ignore it—address it right away to prevent further damage. This quick daily check takes just a few minutes but can catch issues before they turn into costly breakdowns for your slurry pump.

Keep the Slurry Pump’s Intake and Discharge Lines Clear

Next up, make sure your slurry pump’s intake and discharge lines stay free of clogs and blockages. Slurry can be thick and full of solids, so it’s easy for debris to build up in the lines over time. A blocked line forces the slurry pump to work harder than it should, which strains the motor and shortens the pump’s life. Every day, take a moment to inspect the lines and clear any buildup with a tool like a rod or high-pressure water spray. By keeping the lines clear, you’ll help your slurry pump operate at peak efficiency without unnecessary stress.

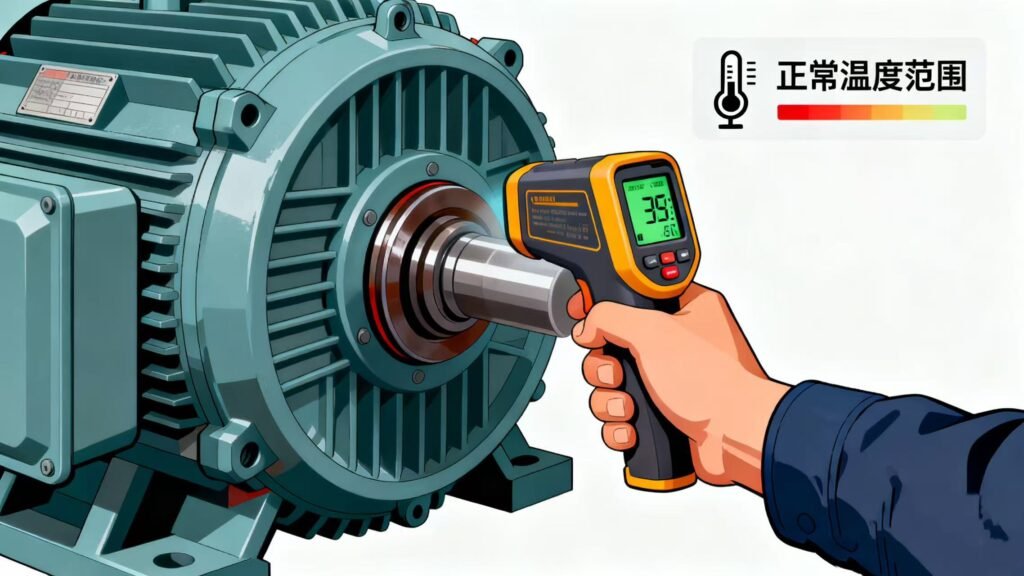

Monitor the Slurry Pump’s Temperature Regularly

Temperature is a key indicator of how well your slurry pump is working, so keep a close eye on it. Most slurry pumps have a normal operating temperature range—check your manufacturer’s guidelines to know what’s ideal for your model. If you notice the slurry pump getting too hot, it could be a sign of a problem like a worn bearing, insufficient lubrication, or a clogged impeller. You can use a simple infrared thermometer to check the temperature quickly. Catching overheating early can prevent major damage to the slurry pump’s motor and other critical components.

Lubricate the Slurry Pump’s Moving Parts Properly

Proper lubrication is like fuel for your slurry pump’s moving parts—it keeps everything running smoothly and reduces friction. Different slurry pumps require different types of lubricants, so be sure to use the one recommended by the manufacturer. Check the lubricant levels regularly and top them off as needed. Also, don’t forget to replace the lubricant at the scheduled intervals—old or dirty lubricant can cause parts to wear out faster. With regular lubrication, your slurry pump’s moving parts will stay in great shape, and the pump will run more quietly and efficiently.

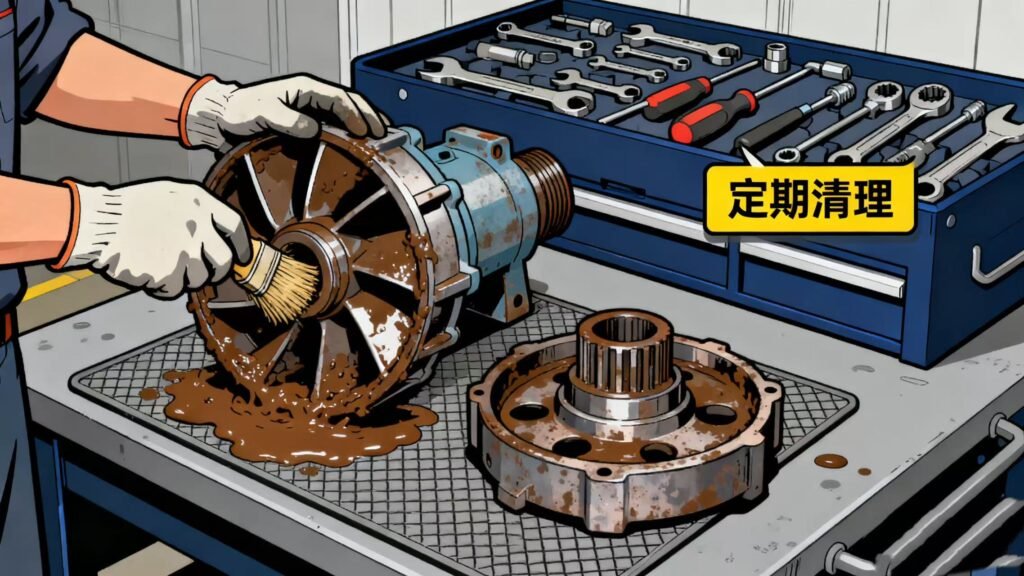

Clean the Slurry Pump’s Impeller and Casing Routinely

The impeller and casing are two of the most important parts of your slurry pump, so keeping them clean is a must. Slurry solids can stick to these parts, causing imbalance and reducing the pump’s performance. Set a regular schedule to take apart the slurry pump’s impeller and casing and clean them thoroughly. Use a brush or scraper to remove any buildup, and make sure there are no cracks or damage. After cleaning, reassemble the parts carefully to ensure a tight fit. A clean impeller and casing will help your slurry pump move slurry more effectively and prevent unnecessary wear and tear.

Check the Slurry Pump’s Seals for Leaks

Seals play a vital role in keeping slurry inside the pump and preventing leaks. Over time, seals can wear out or become damaged, leading to leaks that waste slurry and can damage other parts of the pump. Inspect the slurry pump’s seals regularly for any signs of leakage, such as wet spots or puddles around the seal area. If you find a leaky seal, replace it immediately—delaying replacement can lead to more serious problems, like corrosion or motor damage. Keeping the seals in good condition will help your slurry pump run more efficiently and avoid costly downtime.

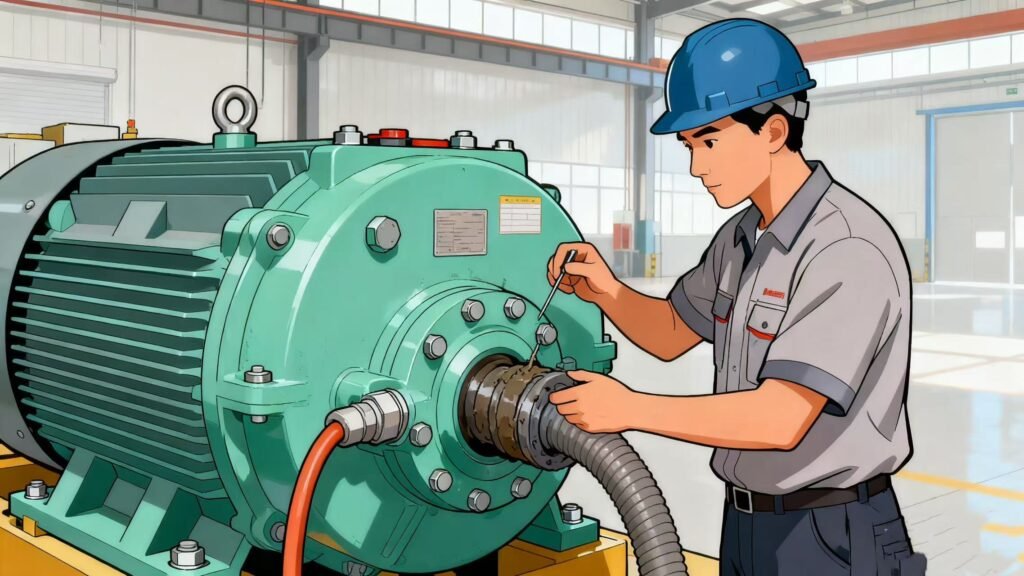

Maintain the Slurry Pump’s Motor in Top Condition

The motor is the heart of your slurry pump, so taking care of it is essential. Check the motor’s wiring regularly for any fraying, loose connections, or signs of overheating. Make sure the motor’s cooling vents are clean and free of debris—blocked vents can cause the motor to overheat and fail. Also, listen for any unusual noises coming from the motor, like grinding or squealing—these can be signs of a problem. If you notice anything odd, shut down the slurry pump and have the motor inspected by a professional. A well-maintained motor will keep your slurry pump running reliably for years.

Follow a Regular Maintenance Schedule for Your Slurry Pump

Consistency is key when it comes to slurry pump care, so create a regular maintenance schedule and stick to it. Work with your team to outline daily, weekly, monthly, and annual tasks—like the visual checks, lubrication, and cleaning we’ve already covered. Keep a log of all maintenance activities so you can track when tasks were completed and spot any patterns or recurring issues. Following a schedule ensures that no important maintenance step is overlooked, and it helps you stay ahead of potential problems. Your slurry pump will reward you with consistent performance and a longer lifespan.

Train Your Team to Handle the Slurry Pump Correctly

Even the best maintenance routine won’t matter if your team doesn’t know how to operate the slurry pump correctly. Make sure all operators are properly trained on how to start, stop, and use the slurry pump safely and efficiently. Teach them to recognize the signs of a problem, like unusual noises, overheating, or leaks, and show them how to perform basic maintenance tasks. A well-trained team will be able to take better care of the slurry pump, reduce the risk of operator error, and keep operations running smoothly. Invest in regular training sessions to keep everyone up to date on the latest care techniques.

Store Spare Parts for Your Slurry Pump On-Site

No matter how well you maintain your slurry pump, there will come a time when you need to replace a part. To avoid lengthy downtime, keep a stock of essential spare parts on-site, like seals, impellers, bearings, and lubricants. Consult your manufacturer’s guidelines to determine which parts are most likely to wear out and need replacement. Having spare parts readily available means you can fix the slurry pump quickly when a part fails, instead of waiting for parts to be delivered. This will help you minimize downtime and keep your operations on track.

Know When to Call a Professional for Slurry Pump Repairs

While regular maintenance can prevent many issues, some problems are best left to the professionals. If you encounter a problem with your slurry pump that you don’t know how to fix—like a damaged motor or a cracked casing—don’t try to repair it yourself. Calling a professional technician who specializes in slurry pumps will ensure that the problem is fixed correctly and safely. Professional repairs can also help prevent further damage to the pump and save you money in the long run. Don’t hesitate to reach out for help when you need it—your slurry pump deserves the best care possible.

Conclusion: Consistent Care Keeps Your Slurry Pump Running Strong

Taking care of your slurry pump doesn’t have to be a chore. With these easy, practical steps, you can keep your slurry pump running well for years, reducing downtime and saving money. From daily visual checks to regular lubrication and professional repairs, every step plays a role in maintaining your slurry pump’s performance. Remember, consistency is key—make slurry pump care a regular part of your routine, and your pump will reward you with reliable, efficient operation. So, start implementing these tips today, and keep your slurry pump working hard for your business.